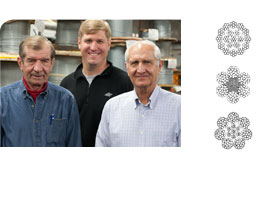

History - Mill Valley Splicing

Three generations of ingenuity, craftsmanship, and pride

Family owned and operated for more than 60 years, Mill Valley Splicing exhibits the characteristics admired of New England residents and their businesses: a strong work ethic and even stronger sense of value and focus on personal attention; innovative thinking; and a deep-rooted dedication to providing well-crafted products, designed to meet the customer's every expectation. Like many of the assemblies they sell, Mill Valley is a business that was custom made to provide excellent rigging solutions.

Mill Valley was founded in 1947 by Walter Boyko. Early on, Walter spent time working at the Wickwire Spencer Wire Mill where he learned wire rope splicing and product fabrication. However, being a boilermaker by trade, he soon took a position at Riley Stoker -- one that would keep him on the road for months at a time.

While working for Riley Stoker, Walter made numberous contacts with individuals in manufacturing and construction. Being industrious, he recognized an opportunity to put his splicing knowledge to good use, and created a small side venture that would earn his family some additional income.

Working in the yard behind the family home, Walter used leftover materials he purchased from Wickwire to fabricate wire rope products, including various types of wire rope slings. He would then sell these products to the manufacturing and construction contacts he had made in his travels. Sooner than anyone expected, Walter had built himself a sizeable customer base, as well as a proper workspace in the form of a garage.

Soon, Walter's sons Jim and Richard joined their father in what was now the family business; with the arrival of offshore oil drilling in the Northeast, Mill Valley Splicing's workload increased dramatically. The family began fabricating 300' pendant lines for rigs in and around Georges Bank. This growth in sales added new equipment to the company's inventory, as well as the need for a new space. In 1978, land was purchased, ground was broken, and by 1982 Mill Valley's facility totaled 12,000 square feet.

Now a third-generation has joined Mill Valley -- Walter's grandson Andrew Boyko plans to continue advancing the products, services, and value the business offers. The Belchertown facility continues to be the site of all Mill Valley's fabrication and testing: housing wire rope, chain, synthetic slings, cordage, and rigging materials; both a 500 ton and 1500 ton National Hydraulic Swaging machines; and a 200' long Lucker test machine with a capacity of 360,000 lb.